PACE weighing and bagging machines offer a great investment for any agricultural or industrial packing operation.

From high-throughput packing houses to family farms, growers and packers of any size can benefit from a bagging solution from the PACE Range. The PACE range can handle anything from potatoes and root vegetables to coal and other solid fuels, powders, bark chips, animal feeds, grain- almost any product you can throw at them.

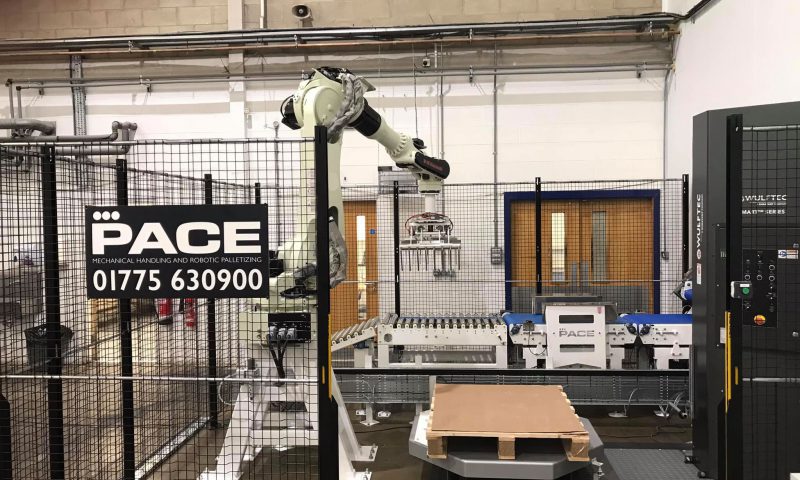

PACE bagging and weighing robot systems typically involve the following components and functionalities:

- Weighing system: The robot is equipped with advanced weighing technology, such as load cells or scales, to accurately measure the weight of the products being packaged. This ensures that each bag or container receives the correct amount of product.

- Product handling: The robot’s end-effector or gripper is designed to handle various types of products, such as grains, powders, liquids, or solid items. It picks up the products from a supply source, such as a conveyor or hopper, and places them into the packaging.

- Bagging or container filling: The robot precisely fills the bags or containers with the appropriate amount of product, ensuring consistency and accuracy in the packaging process. It can adapt to different bag sizes, container shapes, and packaging requirements.

- Sealing and closing: After the bag or container is filled, the robot may also be equipped with sealing mechanisms, such as heat sealers or adhesive applicators, to securely close and seal the packaging. This ensures product integrity and prevents contamination or spillage.

- Quality control and labeling: Bagging and weighing robots can incorporate vision systems or sensors to perform quality control checks, such as checking for proper filling levels or detecting defects in the packaging. They may also have the capability to print and apply labels or barcodes on the bags or containers for traceability and identification purposes.

The benefits of PACE bagging and weighing robots include increased productivity, improved accuracy, reduced labor costs, and enhanced product quality and consistency. Our robots can handle high-volume packaging operations with speed and precision, minimising human error and achieving consistent weight and filling levels. They also contribute to improved workplace safety by automating physically demanding tasks.