Robot palletising systems are advanced automation solutions designed to streamline and optimise the palletising process in various industries.

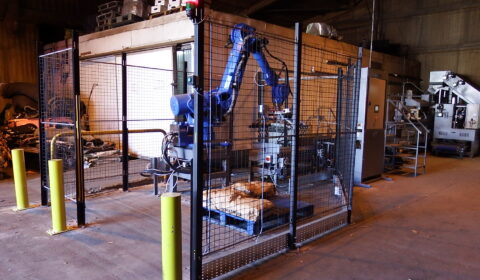

These systems employ sophisticated robotic arms equipped with sensors and grippers to efficiently handle and arrange items onto pallets, eliminating the need for manual labor and reducing human errors. They can handle a wide range of products, from boxes and bags to containers and crates, with precision and speed.

Robot palletising systems offer flexibility in terms of layout and configuration, allowing them to adapt to different production environments and accommodate changing needs. With their ability to operate continuously and consistently, these systems enhance productivity, improve efficiency, and ensure consistent product quality.

By automating the palletising process, businesses can save time, reduce costs, and enhance overall operational efficiency, making robot palletising systems an invaluable asset in modern manufacturing and logistics industries.